Adhesive Consumption Calculations

Talk to an expert for help determining your adhesive requirements.

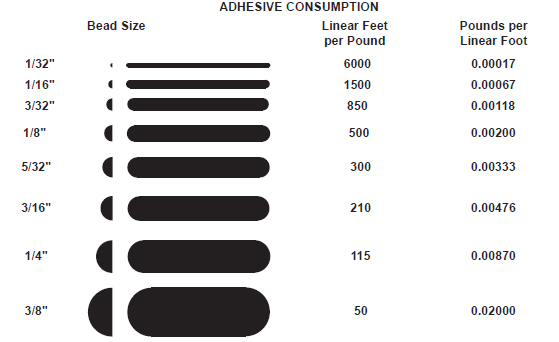

This chart can be used to calculate an approximate Usage Rate.

Usage Rate

How much adhesive you will be using per hour (lb/hour) by an assembly process.

- Example: Your part uses a 3/16″ bead that is 10 ft long, and you produce 200 parts per hour.

- Calculation: Using the table above, the approximate weight of a 3/16″ bead is 0.00476 lb per linear foot. 0.00476 lb per ft x 10 ft bead (per part) = 0.0476 lb per part. 200 parts x 0.0476 lb per part = approx. 10 lb per hour usage rate.

Melt Rate

The rate in lb per hour that a hot melt tank system can melt a specific adhesive or sealant.

- Usage Rate should not exceed Melt Rate.

- Not all hot melts or sealants melt at the same rate. Viscosity, softening point, and other material properties can drastically change the rate that a hot melt unit can melt an adhesive.

- Melt Tank Capacity – The size of the melt tank and the Usage Rate will determine how often adhesive should be added to the tank.