A Record of Innovation … A Focus on Satisfaction

Hot Melt Technologies was founded in 1981. Today with thousands of satisfied customers around the world, HMT remains true to our original vision and purpose. We have grown the right way … focused, steady and carefully. We did not expand through mergers or acquisitions; we did not resort to copy-cat engineering. Instead, we paid close attention to the challenges confronting our customers; we identified unmet needs; and we developed the systems, components and programs to meet those needs.

By doing it the right way, HMT built more than just a company. We built a reputation as the “go-to” team for everything hot melt — one innovation and one satisfied hot melt customer at a time.

1994

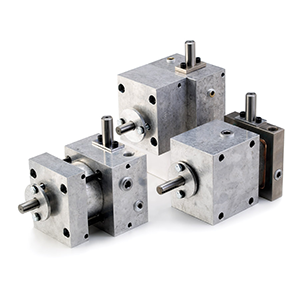

HMT develops a complete line of interchangeable, positive-displacement spur gear pumps combining the wear-resistance of hardened steel with the heat conductivity of aluminum.

1997

HMT is certified compliant to the ISO-9001:2015 Quality Standard.

1998

2000

HMT unveils its first-generation Genesys System Controls for ProFlex and Benchmark Systems. These new “G” series modules enhance process control, improve safety and offer easier maintenance.

2005

HMT develops DG-2000 cable-less Handguns bringing new benefits to users in the woodworking and cabinet-making industries.

2006

HMT develops the ROF auxiliary melt grid for ProFlex adhesive supply units. This auxiliary melt grid effectively doubles the melt rate without overheating or degrading the adhesive.

2007

2014

HMT introduced its 4th Generation Benchmark and ProFlex system temperature and process controllers with improved microprocessor control features and anti-static protection and built in GFEP protections.

2019

HMT equipment is recognized by ETL to meet UL and CSA electrical safety standards.

Going forward, watch for more innovations from Hot Melt Technologies with new technologies and programs that help improve performance, ensure reliability, assure value … and enhance your satisfaction.